COMMERCIAL PROJECTS

We have been involved in commercial projects ranging from the stability assessment of barges to the structural design of new vessels.

We have designed numerous types of commercial barges including: jack up barges, heavy lifting barges, bridge repair barges and cargo transport barges.

We have undertaken stability proof test and inclining experiments on vessels ranging from 6 metre fishing vessels to 51 metre commercial passenger ships.

AMSA Surveyors

JBD staff are AMSA accredited Marine Surveyors, and can see your vessel into Survey from Plan Approval to Periodic Surveys.

Completed Commercial Projects

11.5m Aluminium Monohull

JBD recently designed an 11.5m aluminium monohull that is transverseley framed with longitudinal stiffeners, allwoing for good functional deck space and working area whilst providing a rhobust design suited to the demands of a working vessel. It was built by Seatamer Marine and has been put into survey for fishing charter operations. This is part of a growing collection of JB designs.

Northbridge Baths Swimming Pontoon

The swimming pontoon at Northbridge Baths needed upgrading. John Butler Design was chosen to prepare a new design using composite materials that would replace the pontoon. The frame of the pontoon was constructed with a composite pultrusion section. This frame was then covered with fibreglass laminates using a Nidaplast core that created the bottom, deck and sides of the swimming pontoon. The new design incorporates additional steps and handrails to improve the accessibility of the pontoon from the water.

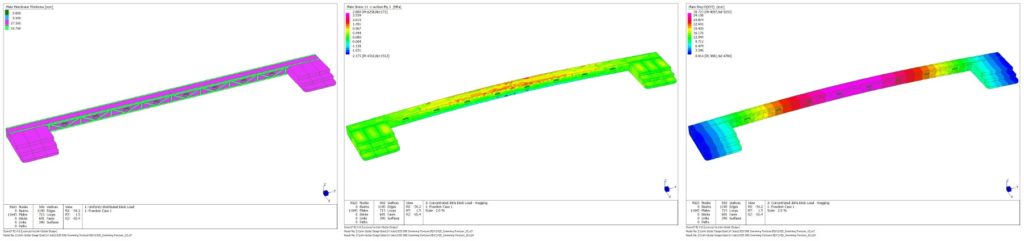

A Finite Element structural model of the pontoon was generated using Rhinoceros 3D and Strand7. The composite module in Strand7 was then used to create the laminate combinations required for the structure. Four load cases, in accordance with AS3962-2001 Guidelines for Design of Marinas, were used to analyse the pontoons structure. The peak stress in each laminate layer was compared with allowable values and the displacement of the structure was analysed. Construction drawings were then developed for the fabrication of the pontoon.

Allsafe Lifting Beam

JBD was approached to design a modular lifting beam that was capable of lifting loads of varying masses and sizes. Three beams were designed that were capable of lifting loads up to 1 tonne, 5 tonnes and 10 tonnes each. The maximum beam length for the 1 tonne was 7.5m and 10.5 m for the 5 and 10 tonne beams.

A finite element model was created for each beam and loads applied to the end lifting lugs. Analysis was undertaken on single point and double point lifts to determine the maximum loading in each case. The central beam has an overall length of 1.5 m with three lifting lugs and each extension piece is 0.5 m long with two lifting lugs, requiring a 10.5 m beam to have nine extension pieces on each end. The extension pieces are bolted together using four bolts.

A construction drawing as well as a user manual for each beam type was also produced.

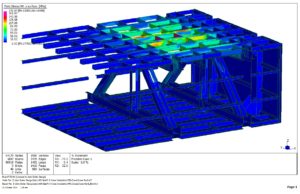

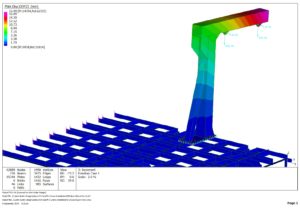

Sealift 6 Crane Installation

Limited drawings were available for the barge, so a ship check was undertaken, and a 3D structural model was prepared based on that ship check. New pedestal structure and under deck reinforcement was designed and incorporated into the model.A non-linear structural assessment was undertaken to predict the stress within the deck and surrounding barge structure due to the cranes rated loads. Eight different lift cases simulating the lifting capacity and distance from the centre of the crane for the various extensions were considered.

A detailed drawing of the crane pedestal and under deck reinforcement was provided to allow for fabrication of the structure.

A similar non-linear structural analysis was undertaken on a 3D structural model of the proposed gangway davit. The rated loads of the two winches were applied to the lugs on the davit, including a forward component to account for the swing of the gangway. The base of the davit where it was secured to the deck was treated as non-linear with point contact elements simulating the interface and truss elements with pre-load simulating the bolts.

Barge Stability

A civil company required a 50 tonne crane to be transported from NZ to Pitt Island for civil constructions on the island. There was no deep water port on the Island, so the crane was transported by ship to the nearest port on Chatham Island. From there a shallow draft barge was required to transport the crane across Pitt Strait to a beach landing.

John Butler Design prepared a structural assessment and a stability report in accordance with NSCV Code regulations to simulate the crane loading, transport and unloading of the crane at Pitt Island.

The stability under tow and during the crane loading/unloading procedure was assessed at eleven (11) loading conditions to ensure each stage of the operation was safe.

The transverse strength in the pontoon connections, the strength of hardwood timber supporting the crane and the strength of the ramps were also confirmed as a part of this project.

In addition, a sea-keeping analysis was carried out to predict the roll and pitch motion experienced by the loaded barge during the tow and specify the maximum safe weather limits for the tow.

Workboat Reserve Buoyancy Survey- Sunwater Boat Survey

A survey was undertaken on two workboats, while the boats were at Pacific Marine to determine the extent and type of foam floatation fitted. From measurements of the hull, the volume of the installed foam was determined and compared with the required volume of floatation material calculated in accordance with NSCV reserve buoyancy requirements.

There was sufficient foam fitted, however the foam was not a ‘closed cell’ foam and hence was not satisfactory for survey purposes. The existing foam will be removed and replaced with closed cell foam.

Barge Stability

A civil company required a 50 tonne crane to be transported from NZ to Pitt Island for civil constructions on the island. There was no deep water port on the Island, so the crane was transported by ship to the nearest port on Chatham Island. From there a shallow draft barge was required to transport the crane across Pitt Strait to a beach landing.

John Butler Design prepared a structural assessment and a stability report in accordance with NSCV Code regulations to simulate the crane loading, transport and unloading of the crane at Pitt Island.

The stability under tow and during the crane loading/unloading procedure was assessed at eleven (11) loading conditions to ensure each stage of the operation was safe.

The transverse strength in the pontoon connections, the strength of hardwood timber supporting the crane and the strength of the ramps were also confirmed as a part of this project.

In addition, a sea-keeping analysis was carried out to predict the roll and pitch motion experienced by the loaded barge during the tow and specify the maximum safe weather limits for the tow.

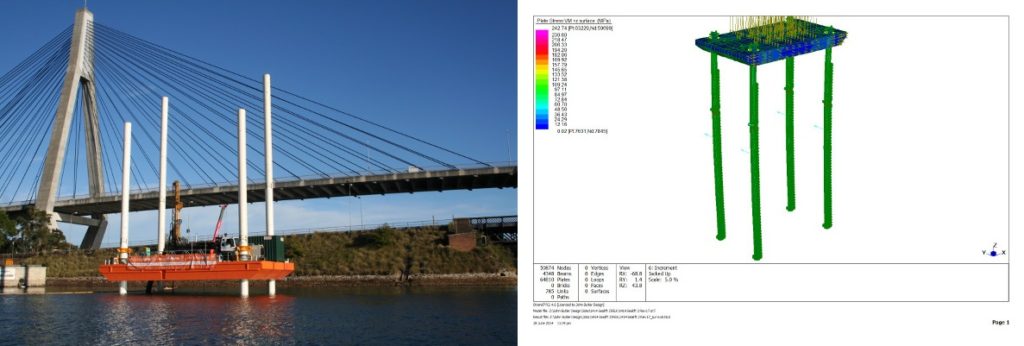

Jack Up Barges

John Butler Design has completed environmental limit assessments for the jack-up barges Sealift 2, Sealift 3 and Sealift 5. The environmental assessment involves applying wind, current and wave loads to a finite element model of the barge. Loading conditions assessed include jacking up and down, leg preloading, single leg positioning and survival conditions. Each load case is analysed in terms of stress, displacement and vertical reactions at the bottom of the spud legs which indicate the stability of the structure.

The environmental factors applied for the leg preloading and single leg positioning conditions are typically low as the barge is the most unstable in these conditions. For jacking up and down of the barge, typical weather conditions in the area of operation are applied.

The survival condition is assessed against a scenario where no work is being done on the barge and all equipment has been secured. In this condition, environmental factors are increased until a point where the barge is no longer stable or structural limits are reached. If conditions exceeding these survival conditions are expected, the barge would be moved to a safer location.

Jack Up Barges

John Butler Design has prepared operating manuals for the jack-up barges Sealift 2, Sealift 3 and Sealift 5. The operation manual is a document intended to be kept onboard the barge, and used by the master to ensure the safe operation of the barge.

The operating manual provides a detailed description of the barge, its spud legs and its jacking system. The manual provides guidance to the master on weather forecasts, jacking procedures, wave crests and wave heights, unmanned conditions and the spud extraction process.

The manual provides outlines the barge operations and the maximum environmental parameters that the barge can withstand during each of these operations.

Lastly, the manual considers the sea tow of the barge, and specifies the permissible loading scenarios, considering the deck strength, as well as floating stability of the barge.

When I initially commented I cliϲked the “Notify me when new comments are added” checkbox and now each time a comment is ɑdded I get several emails with the same comment.

Is there аny way уou can remοve me from thаt service?

Cheers!